ALL-RUSSIAN SCIENTIFIC RESEARCH

INSTITUTE OF AVIATION MATERIALS

INSTITUTE OF AVIATION MATERIALS

+7(499) 261-86-77

admin@viam.ru

VIAM presented its inventions in additive technologies at the international exhibition formnext-2019

VIAM presented its inventions in additive technologies at the international exhibition formnext-2019

On November 19th till November 22nd in Frankfurt-am-Maine the largest international exhibition-conference on additive technologies and 3D-printing – Formnext-2019 – took place in the Messe Frankfurt Exhibition Center. The Formnext exhibition annually attracts hundreds of market leading companies.

FORMNEXT 2019 is held under the slogan “Turning ideas into reality”. This is the place where experts from various fields meet to discover the complex world of additive manufacturing over the whole range of materials used as well as commercial 3-D printing and other innovative technologies.

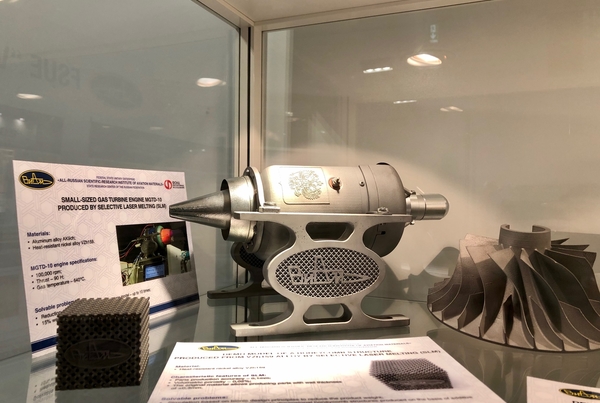

The All-Russian Scientific Research Institute of Aviation Materials (VIAM) presented its latest inventions in the field of additive technologies. The participants and guests of the exhibition were able to have a look at the samples of aeronautical equipment parts produced by means of selective laser melting. For instance, at the Institute’s booth there was presented a combustion chamber swirler of a gas turbine engine, stabilizer and low-emission combustion chamber atomizer, gas turbine engine blades and parts for a gas turbine unit itself. The visitors were able to see small-sized gas turbine engine (MGTD-10) made on the basis of VIAM additive manufacturing.

It is necessary to note that the VIAM specialists have gathered much experience in the field of additive technologies. One of the most important achievements of the Institute in this field is the development of the first Russian end-to-end additive manufacturing which includes all process stages: from melting of charging blanks and its atomization to synthesis of final parts and their post processing. Moreover, the current basis allows VIAM to develop a batch low-tonnage manufacturing of metal powder compositions (up to 190 tons a year). Nowadays VIAM has already designed more than 10 types of metal powder compositions for the technologies of selective laser melting, electron-beam melting and direct laser deposition.