ALL-RUSSIAN SCIENTIFIC RESEARCH

INSTITUTE OF AVIATION MATERIALS

INSTITUTE OF AVIATION MATERIALS

+7(499) 261-86-77

admin@viam.ru

Laboratory-research building

The laboratory-research building is equipped with up-to-date research equipment and includes the following complexes:

- Physical and mechanical tests;

- Thermal characteristic researches;

- Accelerated climatic tests;

- Metallographic examinations and researches of surface destruction of polymer composite materials;

- Non-destructive testing;

- Research of coating properties variations;

- Analytical laboratory.

PHYSICAL AND MECHANICAL TESTS

For assessment of changes of mechanical properties of materials and structures in the course of climatic tests G. V. Akimov GCTC is equipped with universal test machines Zwick Z10/100. Universal electromechanical machines allow to carry out mechanical testing of materials at tension, compression, bending and fatigue tests with up to 0.5 Hz frequency.

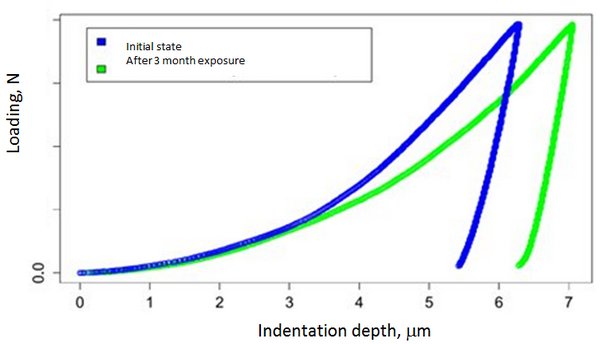

The universal hardness-testing machine Zwick ZHU0.2/Z2.5 allows to carry out hardness measurements on the base of loading diagrams. Continuous recording of loading diagrams allows to carry out numerous measurements in completely automatic mode according to ASTM E2546 standard. Methodological works on research of micromechanical properties of surface are carried out at G. V. Akimov GCTC for corrosion and aging diagnostics at the initial stages when reliable results of standard methods of assessment of material properties are not achievable. The developed technique is used for assessment of aluminum alloys corrosion, researches of seasonal variations of atmosphere corrosivity, an influence of impregnants on mechanical properties of wood and for studying of embrittlement and degradation of organic glasses and paint coatings.

Besides of free exposure, application of operational loadings such as cyclic mechanical loadings and impact loadings is used at G. V. Akimov GCTC to simulate real conditions of operation.

Pulsator Amsler (Germany) provides conduction of fatigue tests within 35-300 Hz frequency in accordance with GOST 25.502, 25.504, 25.507, ASTM E-399, E-647. Distinctive feature of such tests is research of not only standard specimens, but also construction-similar elements.

Application of cyclic loading allows evaluation of the combined impact of environmental factors and mechanical loadings for more exact assessment of service life.

The same importance for development of parts and structural components is determination of impact strength and nature of damages both in initial state and during climatic tests. The same as in the case of fatigue tests, similar tests are carried out at G. V. Akimov GCTC in combination with climatic attacks.

The fatigue tests bay is equipped with vertical impact testing machine Coesfeld Materialtest (Germany) allowing to make regulated impact damages and to plot loading diagrams according to ASTM D 7136/D 7136М. In combination with climatic tests carried out at G. V. Akimov GCTC application of such regulated impacts allows one to study an influence of impact damages on operational properties of materials.

RESEARCH OF THERMOMECHANICAL PROPERTIES OF MATERIALS

Glass-transition temperature and elastic modulus change in the course of operation of PCM under action of environmental factors. Units for thermomechanical analysis allow to high accuracy measurement of these characteristics of materials within wide temperature range.

Netzsch DMA 242 D unit allows registration of changes in linear sizes of specimens at bending, tension, shift, penetration under action of external loadings (from 0.001 up to 16 N) with adjustable frequency (from 0.01 up to 100 Hz) and temperature (from-170 up to +600°С). Conduction of tests both in air and in inert gas or in liquid is possible as well. Linseis TMA PT 600LT unit for thermomechanical analysis allows to investigate changes of phase transformations temperature of materials in the course of climatic tests by dilatometry method.

ACCELERATED CLIMATIC TESTS

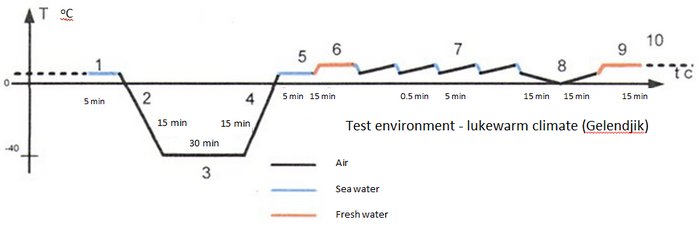

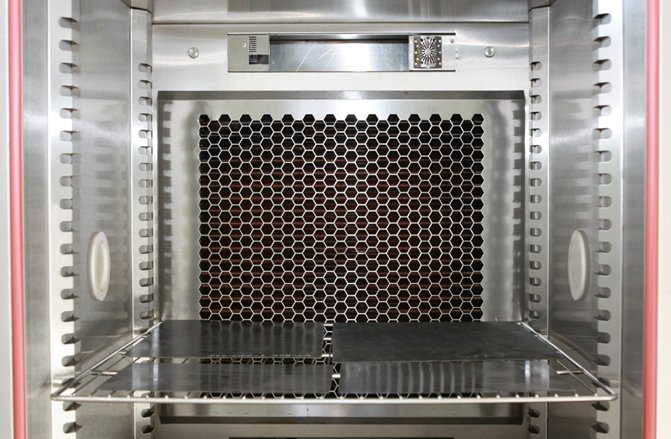

For tests in the conditions approximated to operational ones, G. V. Akimov GCTC carries out not only field exposure of specimens and articles, but also comprehensive cyclic tests combining action of the seaside atmosphere and operational factors (mechanical loading, enhanced and lowered temperatures).

Tests of a fragment of a radio-transparent panel of Be-200 aircraft hull bottom can serve as an example of an integrated approach to creation of test conditions approximated to operational ones. The panel is subjected to attacks of climatic factors, such as exposure in open air, low temperature (down to - 40°С), immersions in seawater.

METALLOGRAPHY AND INVESTIGATION OF DESTRUCTION OF POLYMER COMPOSITE MATERIALS SURFACE

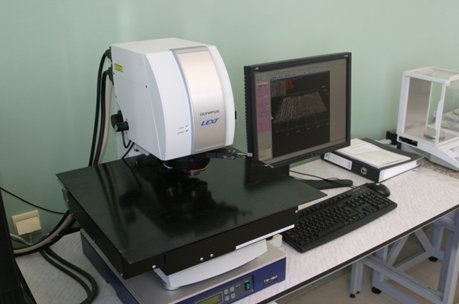

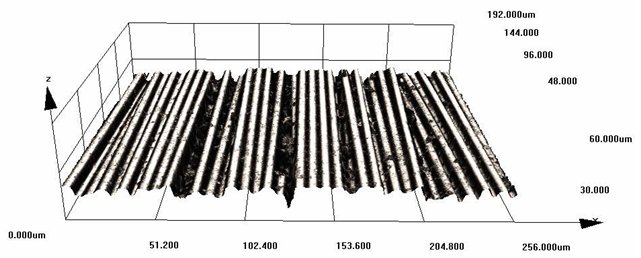

For detection of changes of materials surface profile on initial stages of climatic ageing, one of the most advanced evaluation methods of surface degradation is the laser scanning microscopy.

The main equipment for investigation of materials surface is confocal laser scanning microscope Olympus LEXT allowing to construct 3D-surface profiles. Application of computer processing of images and fractoral analysis makes it possible to estimate destruction of PCM surface layers in the course of climatic ageing already in 3 months after starting tests.

Application of stereomicroscope Olympus SZX 10 with optics of the highest quality (magnification - up to ?126) allows to study specimens surface, to evaluate surface damage square with programmed processing of digital image. Usage of metallographic microscope Olympus GX51 ( total magnification - up to ?1000) allows to study the depth and character of corrosion damages on metallographic microsections with the use of programmed processing of digital images (structural and phase composition of alloy, average/maximal depth of damages, % of surface damage, etc.)

NON-DESTRUCTIVE CONTROL

For control of articles for the presence of internal defects of different types, formed in the course of testing or appeared at production, which can not be found visually, G.V.Akimov GCTC is equipped with up-to-date apparatus for non-destructive control.

For detection of corrosion failures of metallic specimens, measurement of metallic coating thickness and electrical conductivity eddy-current flaw detector Elotest is used. Portable thermoviewer Hot Find DXT with measurement range from -20 up to +250°C and ±2% accuracy of reading values is used for distance control of temperature distribution on surface of articles.

Ultrasonic flaw detector Olympus OmniScan MX2 based on phased arrays is used for detection of failures in composite materials.

Eddy-current Intromet N2 and ultrasonic Elcometer 456 grade thickness gauges are used for non-destructive control of metal and non-metallic coating thickness.

STUDY OF COATING PROPERTIES CHANGE

Paint-and- lacquer coatings not only protect materials from environmental influence , but also have a decorative function. Evaluation of change of paint-and- lacquer coating color in the course of testing is carried out with spectrophotometer X-Rite SP-64. Glossmeters BF allow to evaluate the loss of luster in the course of tests.Depending on the type of a paint-and- lacquer coating, measurement of luster loss is carried out at different reflection angles (45 and 60 grad).

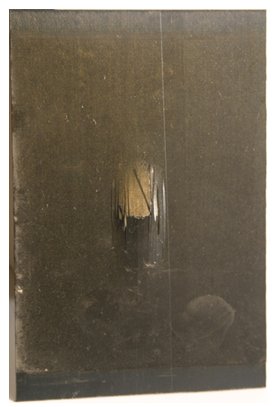

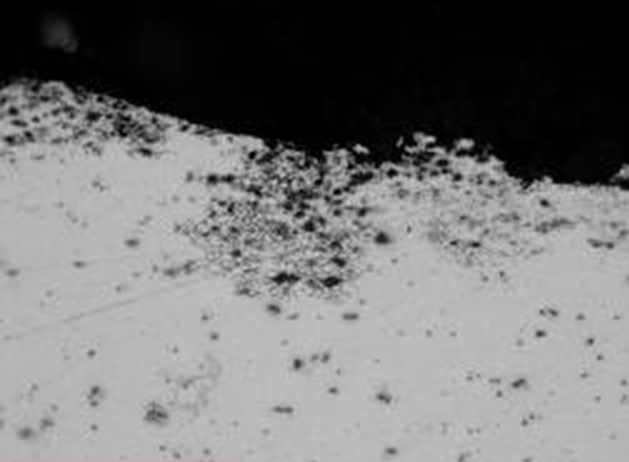

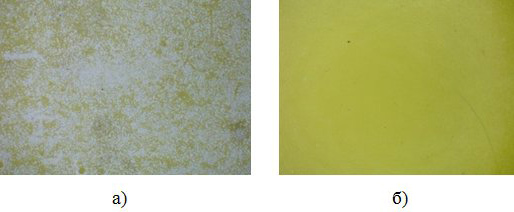

Macrostructure of coating fragment after 12 years exposure under field atmospheric conditions of G.V. Akimov GCTC.

(а) face and (b) reverse side