ALL-RUSSIAN SCIENTIFIC RESEARCH

INSTITUTE OF AVIATION MATERIALS

INSTITUTE OF AVIATION MATERIALS

+7(499) 261-86-77

admin@viam.ru

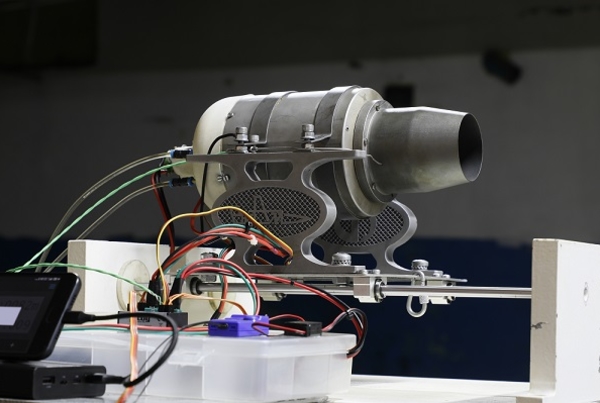

Flight trials of a first russian small-size gas-turbine engine MGTD-20

Flight trials of a first russian small-size gas-turbine engine MGTD-20

The flight trials of the first Russian small-size gas-turbine engine MGTD-20 were run successfully at the base of “Kazanbash” aviation center (the Republic of Tatarstan). The engine was manufactured by selective laser sintering from Russian metal powder compositions on the basis of full cycle additive production developed in VIAM.

Power unit with maximum thrust of 22 kilogram-force has been developed as a part of a joint project of the Russian Foundation for Advanced Research Projects, FSUE “VIAM” and R&D company “OKB n.a. M.P. Simonov”, JSC.

A lightweight unmanned aerial vehicle A30 by R&D company “OKB n.a. M.P. Simonov”, JSC was used as a flying laboratory for the trials. Span clearance of the UAV is 3 meters; takeoff weight is 40 kg including the useful load of up to 10 kg.

During the first trial flight according to a given program, the UAV passed in an autopilot mode along the route points at an altitude of 170 meters with an average speed of 130 km/h, after which it landed successfully.

After manufacturing and testing the engines MGTD-10 and MGTD-20 by its own design VIAM with the support of the Russian Foundation for Advanced Research Projects has become the first Russian and the second world company after General Electric who made the operating engine by additive production.

VIAM together with the R&D company “OKB n.a. M.P. Simonov”, JSC has been performing the project of the Russian Foundation for Advanced Research Projects for the development of the new generation materials for additive technologies of manufacturing structural elements of aircraft and rocket engines (code “Tantal”) since November of 2015. Under the project a line of promising small-size gas-turbine engines in the thrust class 10, 20, 125 and 150 kgf was developed, manufactured and tested on the basis of additive production using specially developed domestic super heat-resistant and high-impact VIAM metal-powder compositions, synthesis technologies, thermal and barothermal treatments, post-processing and control.

A range of the designed alloys has overcome the foreign analogues for more than 20%. Due to the new technology it has become possible to shorten the time for preparation and production of the main engine elements for more than 20 times, at the same time the expenses have been twice reduced.

In 2020 the bench endurance tests of engines MGTD-10, MGTD-20 and MGTD-125 were performed successfully; these engines were the first that had been manufactured in Russia by VIAM and R&D company “OKB n.a. M.P. Simonov” by additive manufacturing and confirmed their stated characteristics.