ALL-RUSSIAN SCIENTIFIC RESEARCH

INSTITUTE OF AVIATION MATERIALS

INSTITUTE OF AVIATION MATERIALS

+7(499) 261-86-77

admin@viam.ru

VIAM took part in MAKS Airshow

VIAM took part in MAKS Airshow

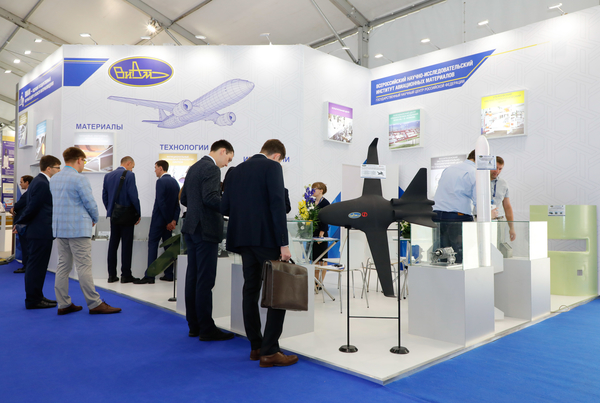

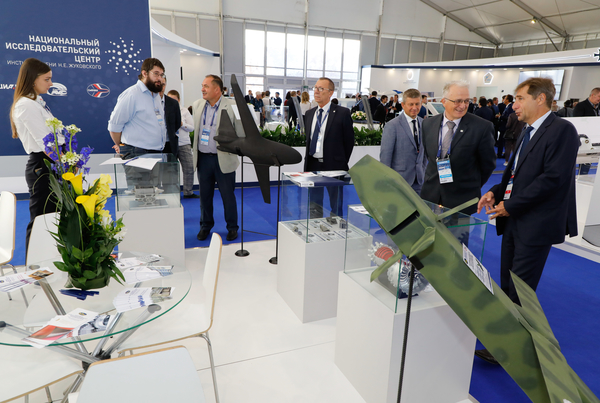

The All-Russian Scientific Research Institute of Aviation Materials (“VIAM”) took part in the International Aviation and Space Salon MAKS-2019, which took place in Zhukovsky from August 27th to September 1st.

The central place of the exposition of VIAM was given to the developments of the Institute in the field of additive technologies — the basis of the new industrial revolution that changed the technological setup itself and led to the changes in the whole production cycle.

The participants and guests of the airshow were able to see the models of unmanned aerial vehicles “printed” on the basis of VIAM additive production. For example, on the Institute booth there was presented the model of experimental twin-engined jet-powered drone; composite materials and epoxy binders developed in VIAM were used in the airframe of this drone. This UAV is capable of conducting flights of up to 200 km distance with minimum 30 kg of useful load at the cruising speed of 420 km/h.

The special place in the VIAM exposition was given to the parts produced by means of selective laser melting for PD-14 engines and PD-35 (baffle plate, jet pipe, and tangential swirl plate), gas turbine plants and liquid rocket engine.

Moreover, on the Institute booth there were presented the samples of gas turbine engine working blades with protective and hardening coatings, as well as prepregs and carbon fiber fabrics designed as a reinforcing agent in PCM – for manufacturing of engine nacelle and constructional elements of the airframe in the aeronautical engineering products.

There were also shown the unique paint coatings, sound and vibration absorbent materials.