ALL-RUSSIAN SCIENTIFIC RESEARCH

INSTITUTE OF AVIATION MATERIALS

INSTITUTE OF AVIATION MATERIALS

+7(499) 261-86-77

admin@viam.ru

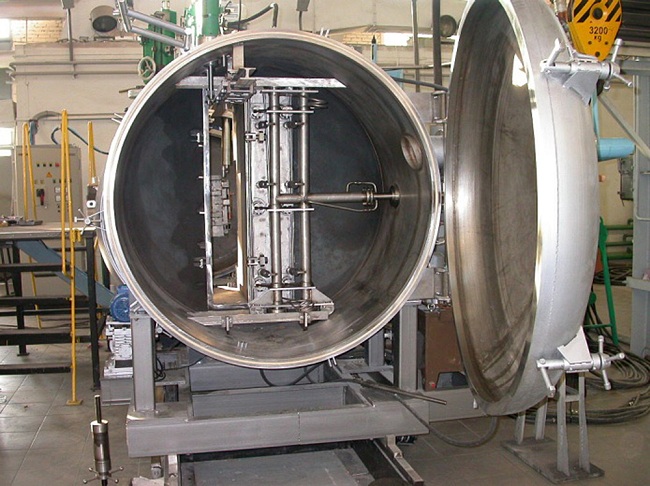

Manufacturing of automated complexes for production of GTE cast intricate-shaped parts with directional and single-crystal structures

Manufacturing of automated complexes for production of GTE cast intricate-shaped parts with directional and single-crystal structures

For realization of promising technological processes VIAM has developed and manufactures vacuum melting-pouring units with principally new thermal assemblies meeting the requirements of modern technological processes and equipped with automated computer control systems.

Units for high-gradient directional solidification provide:

- cooling efficiency of castings is 2.5-5 times higher than that implemented in foreign units by Bridgemen method;

- obtaining of homogeneous fine-dendritic structure in castings;

- 10-20% increase of strength and fatigue characteristics of alloys;

- increase of yield in terms of blades macrostructure.

The following units are applied for serial production of blades with directional and single-crystal structures under condition of temperature gradient G ? 100 degree/cm: UVNK-9A – for blade casting up to 300 mm;

Technical data of UVNK-9A unit

|

Power consumption, kW |

250 |

|---|---|

|

Operating environment: vacuum, Pa | mm Hg |

6,65·10-1 | 5 - 10-3 |

|

Mass of metal in crucible, kg |

10 – 15 |

|

Metal temperature in crucible, °С |

1700 |

|

Mould preheating furnace temperature, °С |

1700 |

|

Capacity of crystallizer with liquid aluminum, kg |

80 |

|

Temperature of liquid-metal cooler, °С |

750-800 |

|

Vertical movement velocity, mm/min |

0,1 – 10, 1,4 – 170 |

|

Mould dimensions, mm |

130х260х350 |

|

Maximum temperature gradient, °С/cm |

60 – 80 |

|

Productivity, moulds/working cycle |

2 |

|

Occupied area, m2 |

47 |

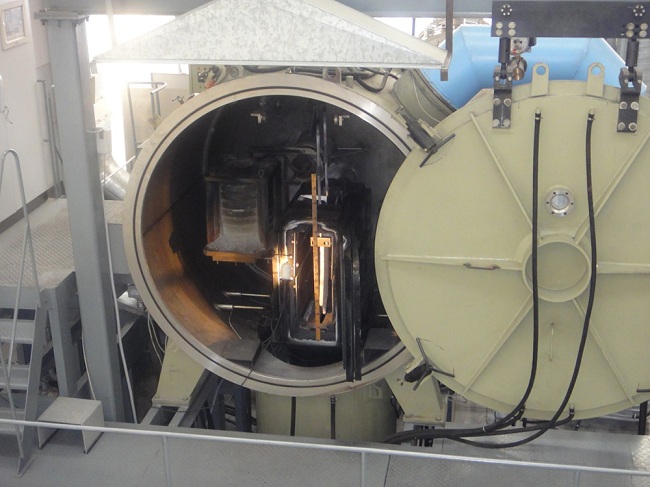

UVNK-10 – for casting of large-sized (up to 800 mm) blades, flaps and spacers of jet nozzle with thrust vector control, intricate-shaped billets for isothermal forging of small-sized engine disks.

Technical data of UVNK-10 unit

|

Power consumption, kW |

450 |

|---|---|

|

Operating environment:: vacuum, Pa | mm Hg |

6,67·10-1 | 5 - 10-3 |

|

Mass of metal in crucible, kg |

60 or 80 |

|

Metal temperature in crucible, °С |

1700 |

|

Mould preheating furnace temperature, °С |

1700 |

|

Capacity of crystallizer with liquid aluminum, kg |

260 |

|

Temperature of liquid-metal cooler, °С |

700-800 |

|

Vertical movement velocity, mm/min |

2 - 120 |

|

Maximum working dimensions of moulds preheating furnace, mm |

250х700х800 |

|

Maximum temperature gradient, °С/cm |

50 – 60 |

|

Productivity, pcs. blades/24 hours |

1-3 |

|

Occupied area, m2 |

65 |

UVNK-15 – for casting of large-sized (up to 600 mm) blades with directional and single-crystal structure for aviation GTE and power GTU.

Technical data of UVNK-15 unit

|

Power consumption, kW |

430 |

|---|---|

|

Operating environment: vacuum, Pa | mm Hg |

6,65·10-1 | 5 - 10-3 |

|

Mass of metal in crucible, kg |

15-25 |

|

Metal temperature in crucible, °С |

1700 |

|

Mould preheating furnace temperature, °С |

1700 |

|

Vertical movement velocity, mm/min |

2 – 100 |

|

Maximum dimensions of casting, mm |

600 |

|

Maximum temperature gradient, °С/cm |

60 – 80 |

|

Productivity, pcs/24 hours |

3–12 |

|

Occupied area, m2 |

50 |

UVNS-6 – commercial high-gradient unit (gradient up to 200 °С/cm) with sluice chamber for casting of hot duct parts of GTE with directional and single-crystal structure (length up to 200 mm).

The unit is equipped with movable heat shields that separate the heating zone from the cooling zone (liquid-metal cooler - tin). The unit is equipped with an industrial computer based system to control main parameters of the production process.

Technical data of UVNS-6 unit

|

Power consumption, kW |

200 |

|---|---|

|

Operating environment: vacuum, Pa | mm Hg |

6,65·10-1 | 5 - 10-3 |

|

Weight of metal in crucible, kg |

8-15 |

|

Metal temperature in crucible, °С |

1700 |

|

Mould preheating furnace temperature, °С |

1700 |

|

Vertical movement velocity, mm/min |

1 – 170 |

|

Working dimensions of moulds preheating furnace, mm |

140 х 360 х 400 |

|

Maximum temperature gradient, °С/cm |

150-200 |

|

Crystallizer capacity with liquid tin, kg |

150 |

|

Temperature of liquid-metal cooler, °С |

300 |

|

Productivity, moulds/working cycle |

2 |

|

Occupied area, m2 |

40 |